Patient Matched TKR

Mr. Nizam has done the largest study in the English literature that looks at Patient Specific Instrumented (Patient Matched Knee replacements) to determine its accuracy in bone resection in Knee replacement surgery.

Published Article: Accuracy of Bone Resection in CT assisted 3D Printed PSI Knee Replacements

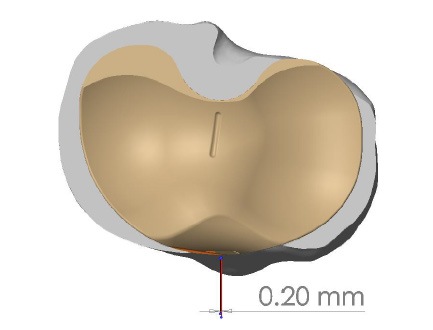

In short Dr. Nizam wanted to see how accurately his surgical precision in resecting arthritic bone was, depending on the 3D printed blocks that were specifically printed and sent from the USA for each patient undergoing Knee Replacement. The study found that 94% of the time the resection error if any was less than 1.5mm (that’s how accurate this knee replacement surgery is). There were NO infections in these patients and 99% of them had excellent range of motion. The amount of bone resected will then determine how well the implant sits, and this directly affects how patients perform and succeed in surgery with achieving excellent clinical outcomes.

The other study that is being conducted will give some answers in the near future with special Xray - EOS scans to determine alignment.

Normally surgeons usually use preoperative Xrays in planning of surgery to template component sizes.

Some of this process of planning and sizing also takes place during surgery.

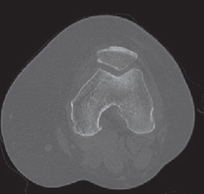

The patient matched instrumentation uses Xrays and 3-dimensional Magnetic Resonance Imaging to give the surgeon a customized template (model) for each patient (to compliment their anatomy). This enables the surgeon to precisely choose prosthesis size and proper alignment and placement.

Customized “blocks or instrumentation” can take upto 2-4 weeks to be made from the time of Xrays and MRI scan as the images have to be sent to specialized a centre. In this case USA.

The Patient Matched Knee Replacement Process

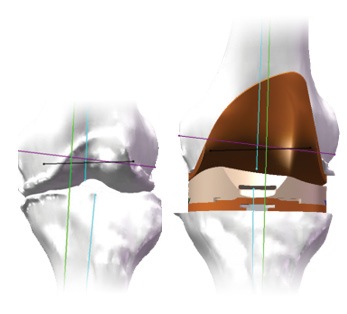

- The patient receives a full leg (Hip, Knee, ankle) CT scan following the Prophecy Protocol – This soft ware available in only certain hospitals

- The Scans are Uploaded to the USA

- Virtual Pre-Operative alignment is performed accordingly

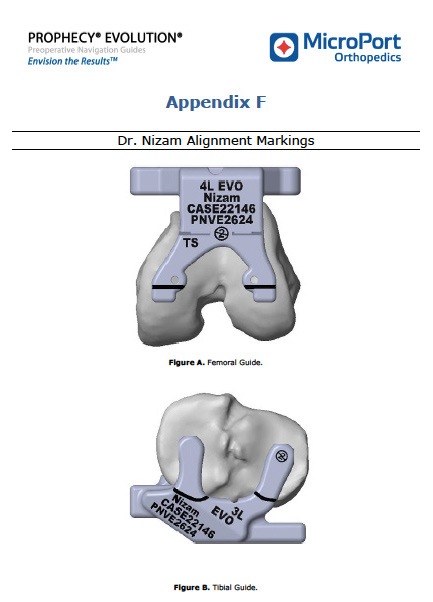

- The surgical plan is then sent from the USA to Dr. Nizam to be approved

Once the surgical plan is sighted it is approved. - The 3D Blocks are then manufactured in the USA and these custom made cutting blocks are sent to Australia

These 3D blocks are specifically designed to provide for accurate alignment, sizing and implant placement to improve function and longevity

Dr. Nizam designed the improvements (special markings) that are now added to the 3D block- measurements and surgical planning to improve this accuracy even more.

Advantages of patient matched knee replacements:

By using these 3D guides, upto 20 different steps can be eliminated cutting down operation times and exposure of the open wound – cutting down the risk of infection

- There is no femoral Intramedullary canal violation – this reduces the incidence of fat embolism into the blood stream and reduces post operative swelling / pain enabling quicker recovery. Standard instrumentation (drilling) can generate high pressures causing fat particles to enter the circulation increasing the risk of fat embolism. The 3D printed blocks eliminate this step.

- Secondary checks can also be performed in addition to the guides to further improve accuracy if needed.

- Standard instrumentation has been reported to result in mal-alignment (greater than 3 degree variation from the mechanical axis) in approximately 28% of knee replacements. These 3D blocks avoid these problems.

![]() Patient Information Brochure – Patient Specific Prophecy Knee Replacement

Patient Information Brochure – Patient Specific Prophecy Knee Replacement

Patient Specific Technologies

Knee Replacement Surgery

Knee Replacement Surgery - Post Surgery

You will need the Adobe Reader to view and print the above documents. ![]()